Engineering Creativity for Neuroscience

Dual-Superfusion Slice Chamber Insert

It is not only a new product; but a unique, worldwide patented idea to support extended survival of brain slices. This brand new improvement of slice chambers for electrophysiological recordings and/or in vitro imaging was developed by Prof. Dr. Norbert Hajos, D.Sc. (email: hajos@koki.hu). The Dual-superfusion Slice Chamber Insert is recommended for all types of slice recordings, but it is indispensable for investigations where oxygen is a limiting factor of neuronal function, e.g. network oscillations (Hajos et al., European Journal of Neuroscience, Vol. 29, pp. 319-327, 2009).

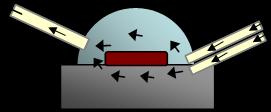

Dual superfusion of submerged slices increases the vitality of cells as oxygen, as well as other materials. They can freely and more effectively diffuse into the thick slices from both sides. In the most widely used slice chambers, where the slices are sitting on a glass cover slip, oxygenation and drug diffusion is achieved only from one side.

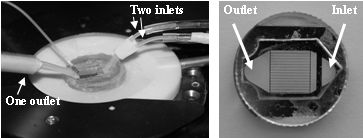

A chamber insert was created where slices sit on a mesh, and the shape of the insert supports laminar flow around the submerged slices ensuring better oxygenation. The mesh divides the chamber into two parts. Both the upper (above the mesh), and the lower (below the mesh) parts of the chamber are 2 mm in height. By using this type of chamber design the flow rate of the superfused solutions can be kept as low as 3-5 ml/min, while the oxygenation of the tissue can be maximally maintained.

The Dual-superfusion Slice Chamber Insert is 20 mm in outer diameter. This diameter was chosen because this way our product is compatible with the most popular brain slice chambers on the market. The mechanical drawing of the plexiglas insert is available for download. Bigger meshes will be introduced later in the same 20 mm outer diameter for human brain slices. Measurements of your existing brain slice chamber to be compatible with the Dual-superfusion Slice Chamber Insert are:

• the diameter of the internal center hole must be larger than 20 mm.

• the effective depth of the internal center hole should be approximately 5 mm or more.

The working (meshed) area of the stainless steel mesh is 7.2 by 7.2 mm.

A description of how to maintain slices in interface conditions is available for download.

A product leaflet of the Dual-Superfusion Slice Chamber Insert is available for download.

A Frequently Asked Questions file about the Dual-Superfusion Slice Chamber Insert is available for download.

Stainless steel mesh

Click on the picture to get it in full size

Click on the picture to get it in full size

One piece of plexiglas insert

Click on the picture to get it in full size

Plexiglas inserts with stainless steel mesh

Click on the picture to get it in full size

Application Tips

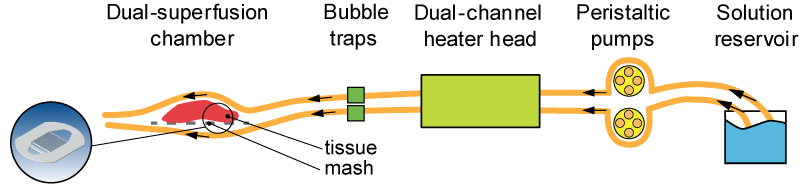

Based on the experience obtained in Prof. Dr. Norbert Hajos' laboratory (Hajos et al., 2009, see above), the temperature and oxygenation of brain slices in the Dual-Superfusion Slice Chamber Insert can be controlled in two ways. Either the experiments should be done at room temperature, then only the flow rate of aCSF (Artificial CerebroSpinal Fluid) has to be set equivalently below and above the slices (e.g. using peristaltic pumps with at least three channels - two inlets and one outlet). Or in case the experiments are desired to be performed at a higher temperature, then not only the flow rate but the temperature as well should be maintained as equivalent as possible below and above the slices. To achieve this, a Dual-channel In-line Solution Heater ISH-D is recommended, where the temperature of the two inlets is controlled in a single heater head to ensure the same temperature.

If you want to use the Dual-Superfusion Slice Chamber Insert in optimal conditions, the temperature of the two independent solution flows should be controlled. For this purpose any kind of 2-channel in-line solution heater and a compatible temperature controller should be used. We recommend using the related products of Supertech Instruments. These are the Dual-channel In-line Solution Heater ISH-D and the compatible Physiological - Biological Temperature Controller TMP-5x. They are the optimal choice because they work as a set and they are optimized for the dual-superfusion survival method.

On the surface of the stainless steel mesh the effects of some unwanted electrochemical changes can be observed after 3 month of usage. If you notice such an effect, please replace the mesh in order to provide the optimal living conditions of your slices.

Some sterilizing gases used in the medical routine destroy the material of the plexiglas inserts chemically. Please take this aspect into account.

We offer the complete assembly "Plexiglas inserts with stainless steel mesh", or the plexiglas spare parts independently. The reason why we offer the vulnerable plexiglas parts is that the outcome of the cleaning process is uncertain in many cases (because of the impact of the cleaning solution on the plexiglas), so it might be easier to simply replace them. The replacement plexiglas parts are identical with the existing parts of the assembly.

Prices

You can find the general warranty and shipping conditions in the beginning of the Services page.

Plexiglas inserts with stainless steel mesh DSSC-1, in other words complete Dual-Superfusion Slice Chamber Insert, assembled version (drop-in improvement to introduce dual-superfusion surviving method in any compatible brain slice chamber): 133 EUR

A pair of plexiglas inserts, without mesh DSSC-P1, for replacement purpose: 28 EUR

Shipping costs upon request.

Copyright @ Supertech Instruments - since 1991